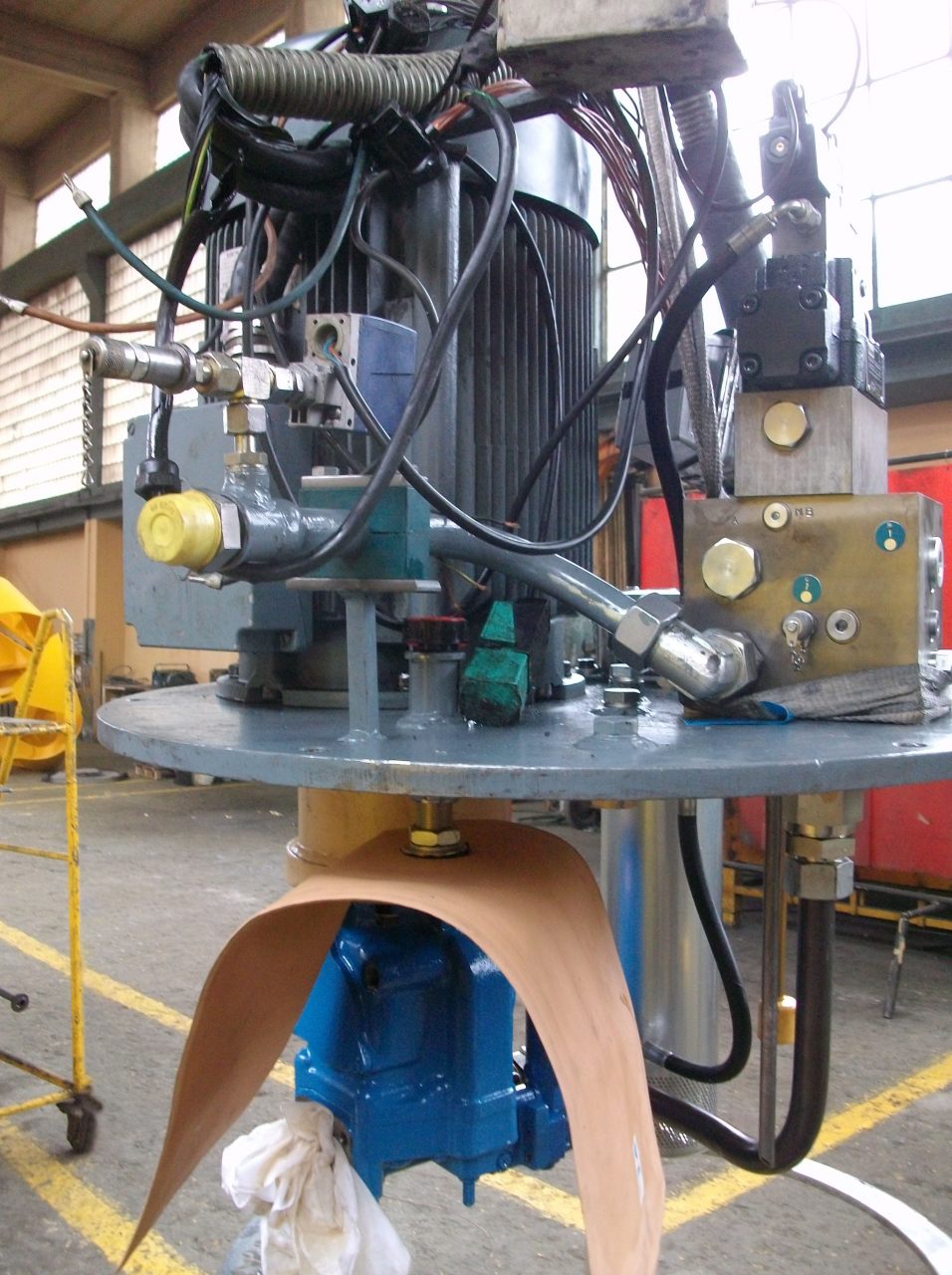

There are different ranges of grapples or claws according to various applications. Among them, the hydraulic range. Hydraulic claws run thanks to the oil inside the crane system. For long-term use, oil characteristics and cleanliness have to be maintained. That is why maintenance for oil is sometimes necessary on some machines.

Constraints

A Spanish manufacturer of hydraulic grapples wanted to improve his systems, so as to avoid too frequent maintenance operations. Oil in such a system has to keep clean so as not to damage components. Oil volume varies inside the tank during use. When volume is lower, air from outside fills in the oil gap. But cranes usually operate in dusty sites. The air coming inside the tank is therefore polluted. This may alter on a short or medium-term the oil quality and thus carry out more frequent maintenance operations.

Our customer was, therefore, looking for a system to protect oil inside the tank. The ideal solution for this has then:

- to be custom-made so as to be installed in the oil tank,

- require few maintenance operations so as not to stop production,

- prevent any oil contact with outside air.

That is why this manufacturer applied to Pronal to design an hydraulic breather.

Pronal solution: the flexible compensator EXP for the crane hydraulic system

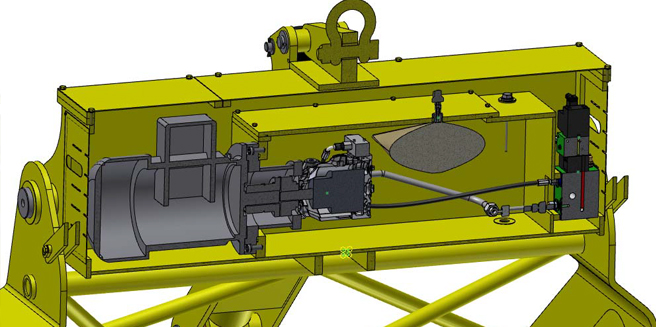

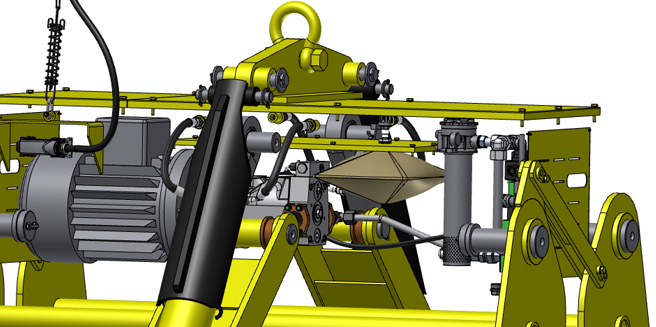

After analyzing customer’s needs and specifications, Pronal proposed an EXP compensator. This hydraulic compensator was custom-made, with the following characteristics:

- size: 490×240 mm,

- a stainless steel insert,

- a center-placed stem for air-inflation,

- nitrile material suitable for this kind of oil,

- and a filter for incoming air.

This hydraulic system is installed inside the tank. Acting as a genuine hydraulic breather, it inflates and deflates according to oil volume variations. The compensator inflates when the oil volume is getting lower. The air cannot, therefore, get in contact with the liquid. The oil is thus protected and keeps its properties. The compensator material is adapted to oil type, working temperature, etc.

This flexible solution for compensation is an alternative to the vacuum breaker. Opposite to the inflatable compensator, the oil breaker filters and let the outside air come in. Air keeps in contact with hydraulic oil and then alters its properties. This solution is, therefore, less reliable than the hydraulic breather.

Conclusion

This manufacturer orders now very regularly hydraulic breathers. This inflatable system saved tremendous hydraulic maintenance times. Thanks to this time-saving, downtimes have been reduced and money has been saved. This was a successful project!

Speakers

Our other projects

Would you like more information on this project?

Vous pouvez contacter nos experts qui sont adeptes de ce genre de projet pour avoir plus d’informations et être conseillé