The anti-lock braking system, aka ABS, operates by preventing the wheels from locking up during harsh braking. After mounting, this has to be tested before being brought into service. Lifting the vehicles is necessary to test this system on each wheel.

Project and constraints

The French manufacturer of buses and coaches, Iveco Bus, needed to lift its vehicles in order to test the ABS-systems. Lifting columns were then used.

The new bus lifting system would then have to be easy-to-use and fast-to-deploy to switch to the next vehicles quickly. Further technical constraints had to be met:

- a distance of 200 mm between the ground and the bus frame,

- lifting height of 50 mm,

- lifting weight of 2 T on the front part and 4T on the rear part of the bus,

- and a little contact surface of 400x50mm.

The contact surface is even reduced for the rear wheels, owing to a damper. The dimensions of the lifting system would thus have to meet those constraints. Iveco bus then chose a flexible and inflatable solution to lift its buses: the pneumatic lifting cushion.

Pronal solution: pneumatic cushion for bus lifting

After analysis of customer’s needs and requests, Pronal supplied a full inflatable system for bus lifting, composed of:

- 1 lifting cushion CLT 10T for rear wheels,

- 1 lifting cushion CLT 34 T for top wheels,

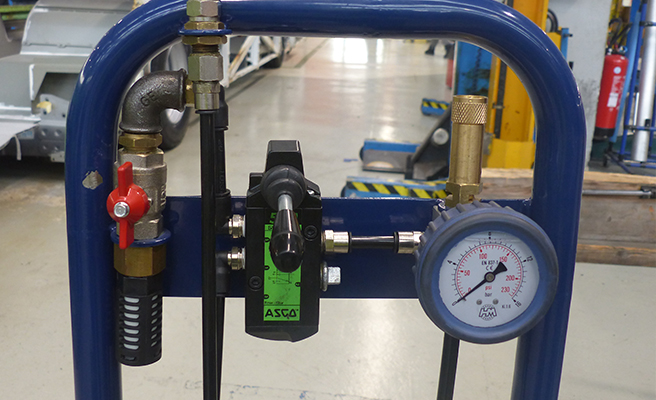

- 1 control panel with “push-button”, ejector and pressure gauge,

- and 1 inflation hose lg.5m.

Placed in front of the wheel, the CLT 43 cushion, once air-inflated, quicky lifts the bus without any frame deformation. In less than 30 seconds, the vehicle is lifted and the ABS-systems then tested. Remote air inflation keeps the operator safe. Moreover, the bus remains stable once lifted, thanks to the cushion’s non-slip fabric and flat surfaces.

Our CLT10 cushion being too small for the real wheels with dampers, stroke has to be reduced. Iveco’s idea: the combination of a trolley and the cushion to reduce the stroke. He set the control panel on the trolley’s grip so as to inflate easily the lifting system. The trolley was placed under the frame and then the cushion did the job.

Advantages and conclusion

Light and easy to handle, the lifting cushions met customer’s expectations in terms of easy and quick solutions. With a bus lifted quickly and without effort, operators can now test ABS-systems more quickly and then switch to the next vehicle.

Materials used

Speakers

Our other projects

Would you like more information on this project?

Vous pouvez contacter nos experts qui sont adeptes de ce genre de projet pour avoir plus d’informations et être conseillé