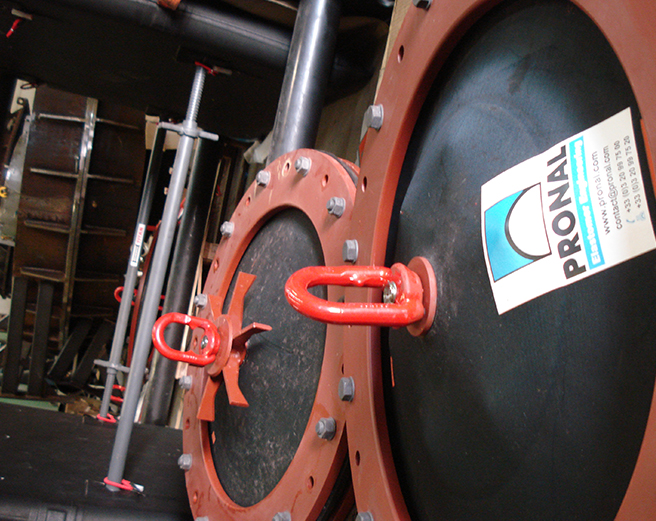

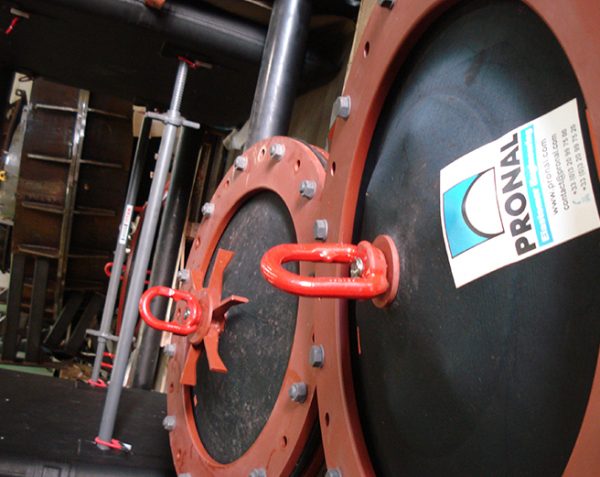

Rip-out diaphragm closure

The Rip-out diaphragm closure, equipped with a cruciform piercing tool, provides different functions:

- buoyancy assistance for large platforms equipped with metal floatation tanks,

- corrosion protection for electrical outlet cables.

Made from high resistance rubber coated fabric and assembled by hot vulcanization, our rip-out diaphragm closure is designed to take into account :

- Leg ID

- Thickness of the leg

- Water depth

This is a solution for your oil & gas project.

Our teams can travel on-site to install your offshore buoyancy kits no matter where you are located ! A complete removal of all rubber parts version is also available.

Advantages

Reliability

- Tightness testing can be implemented before installation

- Penetration and rip-diameter testing can also be performed

- Simulation and calculation of the force required to puncture the diaphragm

Safety

- Air and water tight

- Suitable for applications at depth

- Ease of installation

Handling

- Locking fixation system

- Insert integrated into the rubber

- Selection of suitable materials

Detailed information

- Material: Synthetic Rubber

- Technique: hot vulcanization in a vacuum autoclave

- Dimensions: min. 6″ (152.4 mm) / 118″ (max. 2997.2 mm)

- Form: cylindrical

- Temperature resistance: +0 / +60°C

- Max. thickness: defined by the clients’ specifications

- Grade of steel: defined by the clients’ specifications

You can not find your dimensions

Our design department employs the best project leaders and designers and will be pleased to develop and create a tailor-made product specially for your unique project.