Stoppers for the chemical cleaning of plate heat exchangers - ONC

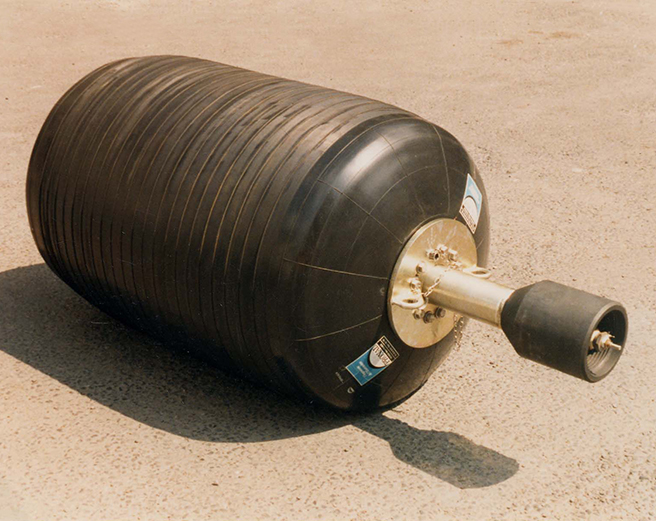

Working in collaboration with EDF, Pronal has developed a stopper system capable of plugging the inlets and outlets of plate heat exchangers. These are stoppers for the chemical cleaning of plate heat exchangers. They are designed for nuclear sites.

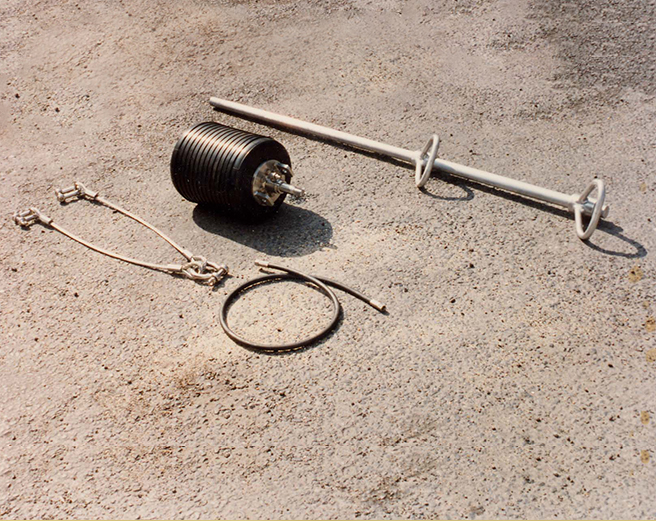

Furthermore, the ONC stoppers can be remotely installed in the pipes using a rod and a cradle to prevent the stopper from being damaged by any abrasive surfaces on the plates.

The stoppers for the chemical cleaning of plate heat exchangers are highly resistant to cleaning fluids. Finally, the inflatable stoppers remain completely air/watertight up to a pressure of 3.4 bar. Morever, different dimensions are available: ONC 240, ONC 280 and ONC 380.

Advantages

Reliability

- High chemical compatibility

- High diametrical dilation

Safety

- High quality

- Highly resistant to chemical products and temperatures

Installation

- System equipped with a rod and cradle for installation

- Stopper can be used portably

Detailed information

- Material: NBR (Nitrile Butadiene Rubber) PMUC-certified

- Technique: hot vulcanisation in a vacuum autoclave

- Dimensions: dia. 240, 280 and 380 mm

- Form: cylindrical

- Inflation: by air

- Temperature resistance: -25°C / +100°C

- Max. inflation pressure: 7 Bar

- Accessories:

- Rod

- Sling

- Cradle

- Supply line

You can not find your dimensions

Our design department employs the best project leaders and designers and will be pleased to develop and create a tailor-made product specially for your unique project.